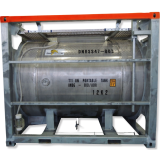

25 BBL IM 101 Transport Tank [S-Style]

25 BBL IM 101 Transport Tank [S-Style]

COMMON USES

Secure transportation and storage of drilling, production, and completion fluids as well as fuel, waste, and other liquids.

Click to add this item to cart.

| Size: | 2438mm x 2235mm x 2261mm (LxWxH) |

| Weight: | 13495 kg |