DRILLED SOLIDS MANAGEMENT

Your one-stop-shop for efficient waste management services.

SERVICES MENU

EQUIPMENT MENU

ONE OF A KIND SOLUTION

Evolving with the new oil & gas industry

As our industry continues to evolve, we are faced with increasing our responsibility to protect the environment in which we operate providing the most efficient and cost-effective solutions available. At Tiger, our objective is to provide superior solids control and zero discharge equipment in conjunction with best-in-class service to our clients.

With over 20 years of experience, Tiger is a leader in the energy services field, providing a full range of cleaning, environmental, and other oilfield services solutions.

Our team of dedicated, hard-working professionals is committed to providing customers with safe, effective and cost-efficient solutions that meet their individual needs. At Tiger, we ensure our team is deeply experienced and highly trained to provide quality service and technical expertise to help our customers every need. Our Drilled Solids Management Services support offshore and land operations from our Trinidad facility. To learn more click here.

SOLIDS MANAGEMENT BENEFITS

- Reduced drilling fluid costs while meeting EPA discharge mandates

- Reduced disposal costs when using DOBM

- Reduction from Environmental Exposure

- Increase penetration rates

- HSE- All of our controlled solids services are being developed using automation to reduce the potential for any health incidents.

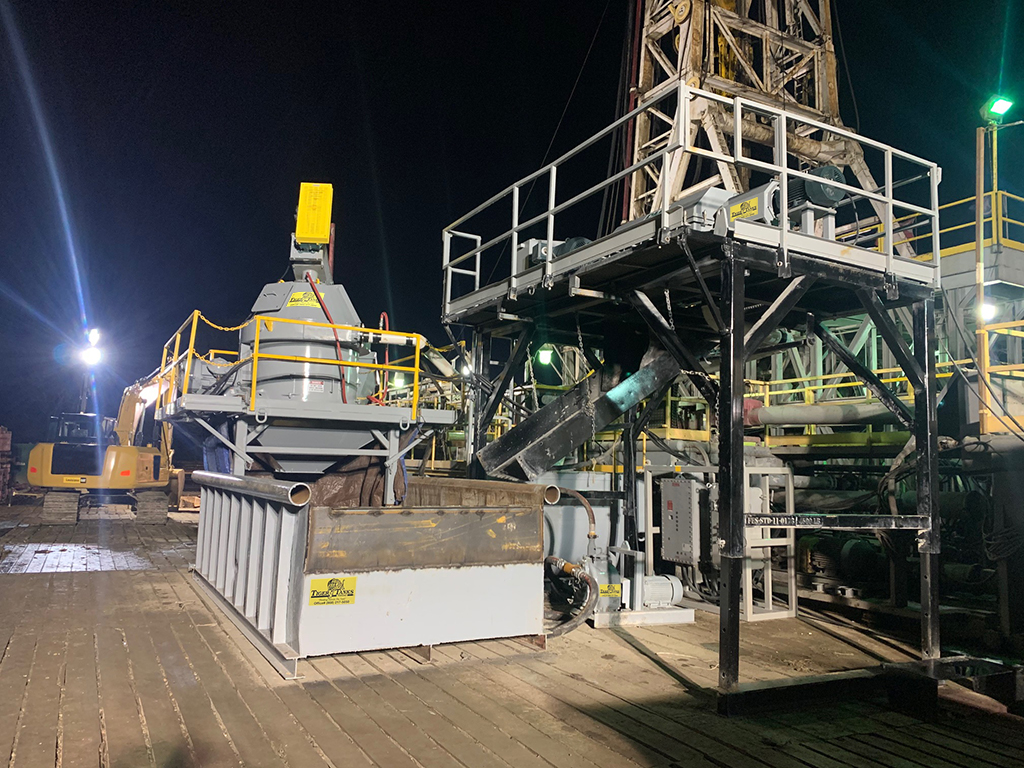

D4 VCD DRYER

PMI’s D4 VCD incorporates a proprietary enclosed gear drive assembly providing a guaranteed Class I – Division 1 and Class I – Division 2 drive system compliance. No other dryer available on the market can make those same claim.

Static electricity is the ignition source in approximately 10% of all chemical fires & explosions. Inadvertent damage to the belt tunnel and/or removal of the access doors leaves static electrical discharge of excessive heat exposed to an electrically

“NEW” ANNULAR CUTTINGS BOX FEED INLET

- Back and Hand Injuries Rank #1 & 2 in Bodily Components Injured at Work

- 20% of all Workplace Injuries are Back Injuries

- 15% of all Workplace Injuries are Lacerations to the Hand

- Injuries are Costly = $26,384 per Claim

- The Solution is Available!

SOLUTIONS DRIVEN

- Zero Discharge & Cuttings Box Solutions

- Drilled Cuttings Conveyance Equipment

- Cuttings Dryers and Drying Shakers

- Automated Tank & Vessel Cleaning

- Rig Vacs & Pressure Washers

- Variable Speed Centrifuges

- Cargo Carrying Equipment

- Automated Rig Cleaning

- Dockside Services

- Dewatering

- Rentals

PRINCIPALS FOR SUCCESS

Time matters to us. PMI utilizes cutting edge technology in conjunction with custom designed software to effectively track assets both locally and globally.

Reliability matters to us. By incorporating new technologies we have eliminated unnecessary components requiring less maintenance allowing personnel to focus primarily on what we were hired to do!